2019

11 weeks

4 people

A reflex is an action that is performed without conscious thought in response to given stimuli. Re:flex is a reconfigurable, programmable material that changes its shape in response to heat.

Imagine a world in which the materials we use are no longer inert, allowing objects to be reshaped by users to suit their needs.

Natural materials and structures constantly respond and adapt to changes in the environment. This makes organisms resilient to change. Yet our built environment is static and does not morph in response to changing conditions as natural structures do.

The idea of a living, breathing material world has captured the imagination of people for centuries. Advancements in smart material technology have allowed us to pursue this vision of active matter. However, where are these materials in our everyday lives?

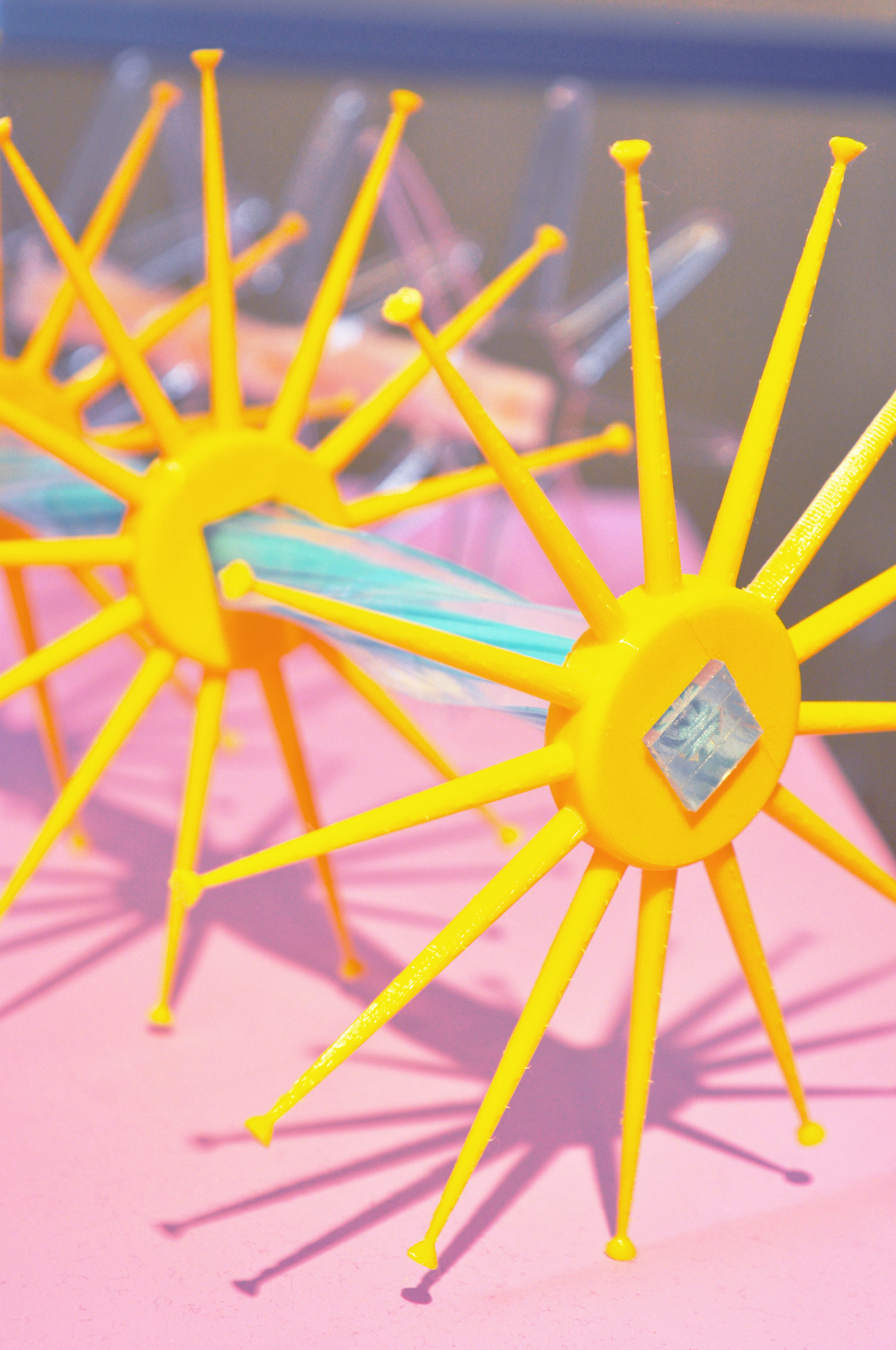

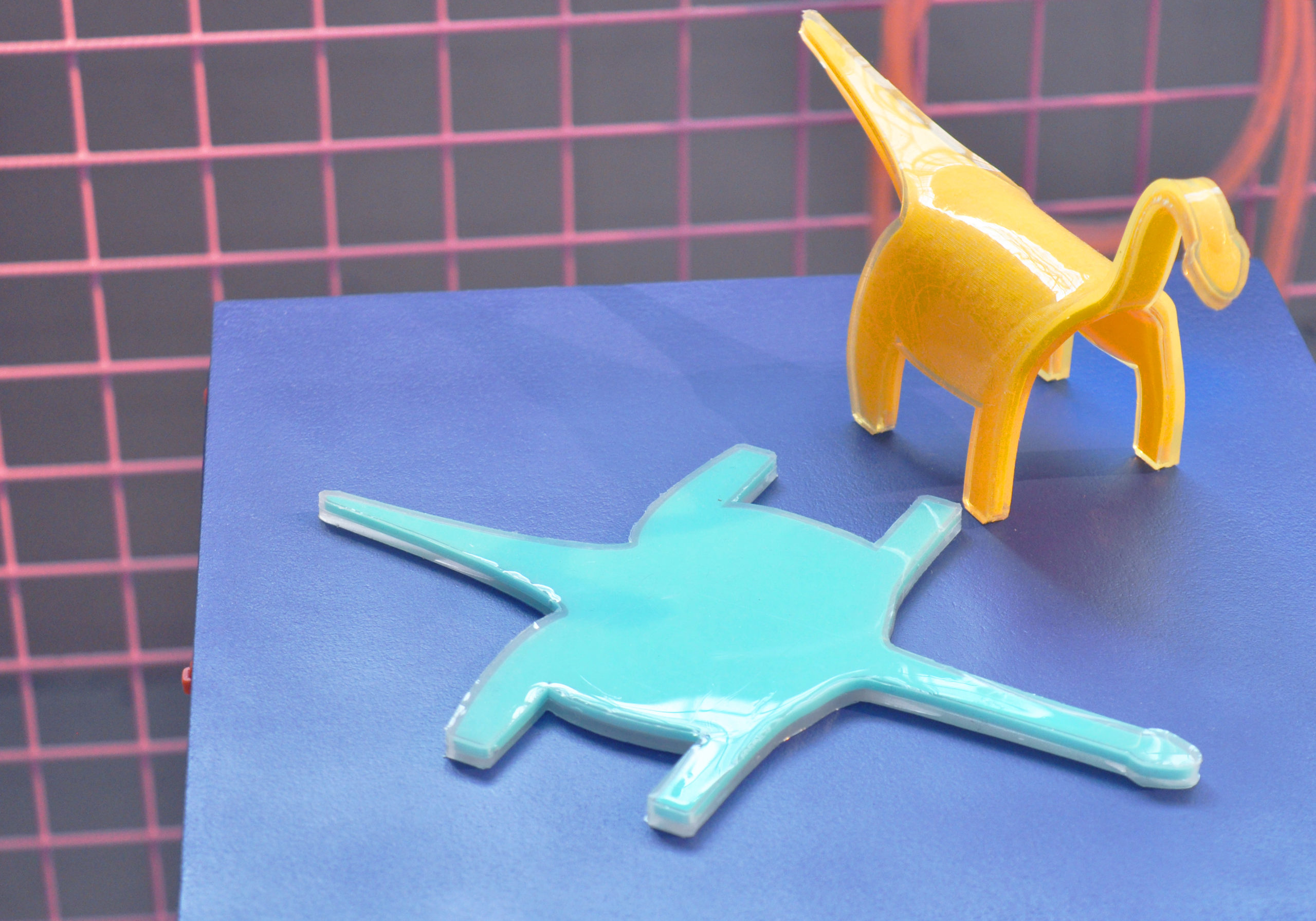

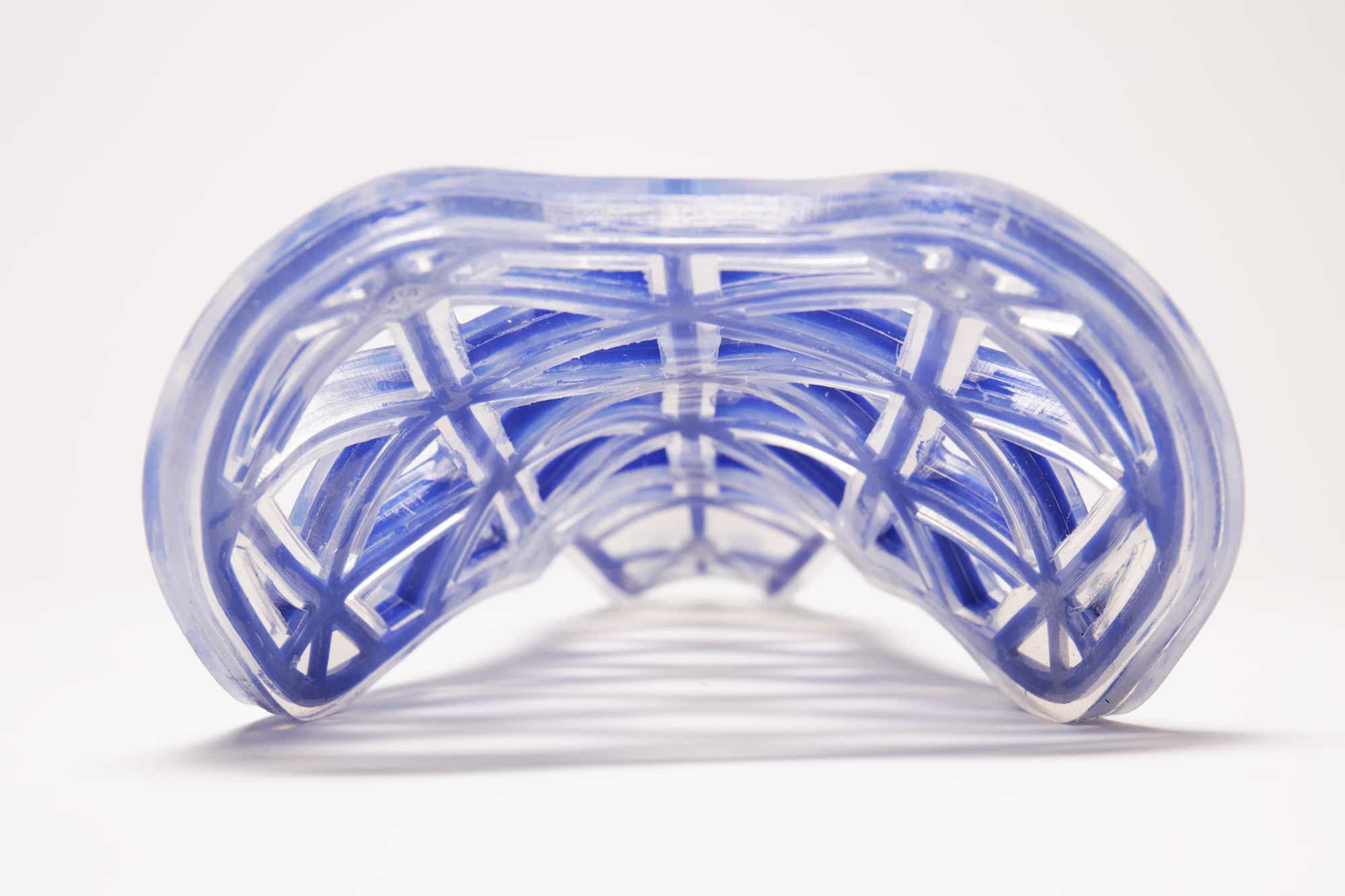

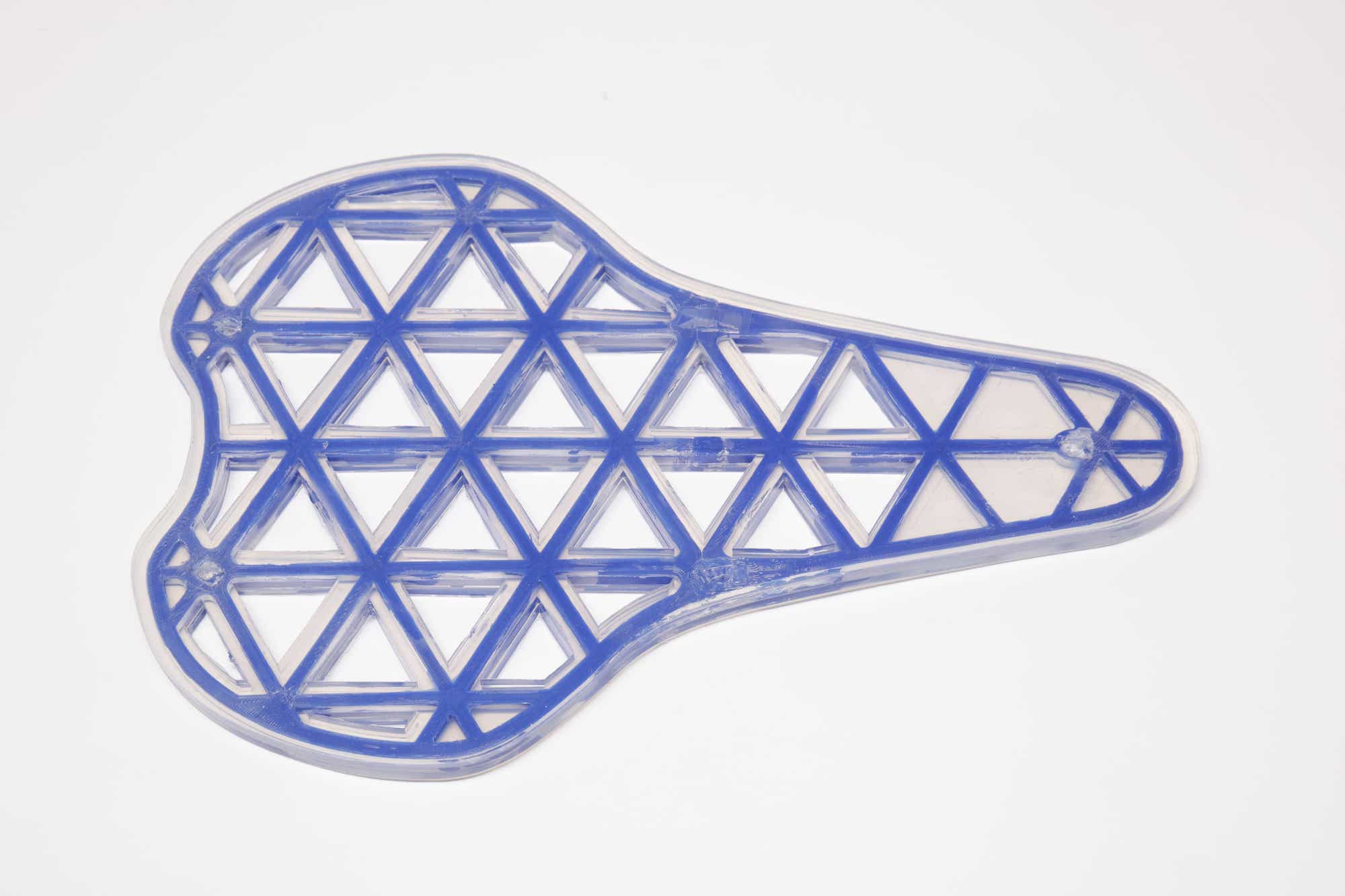

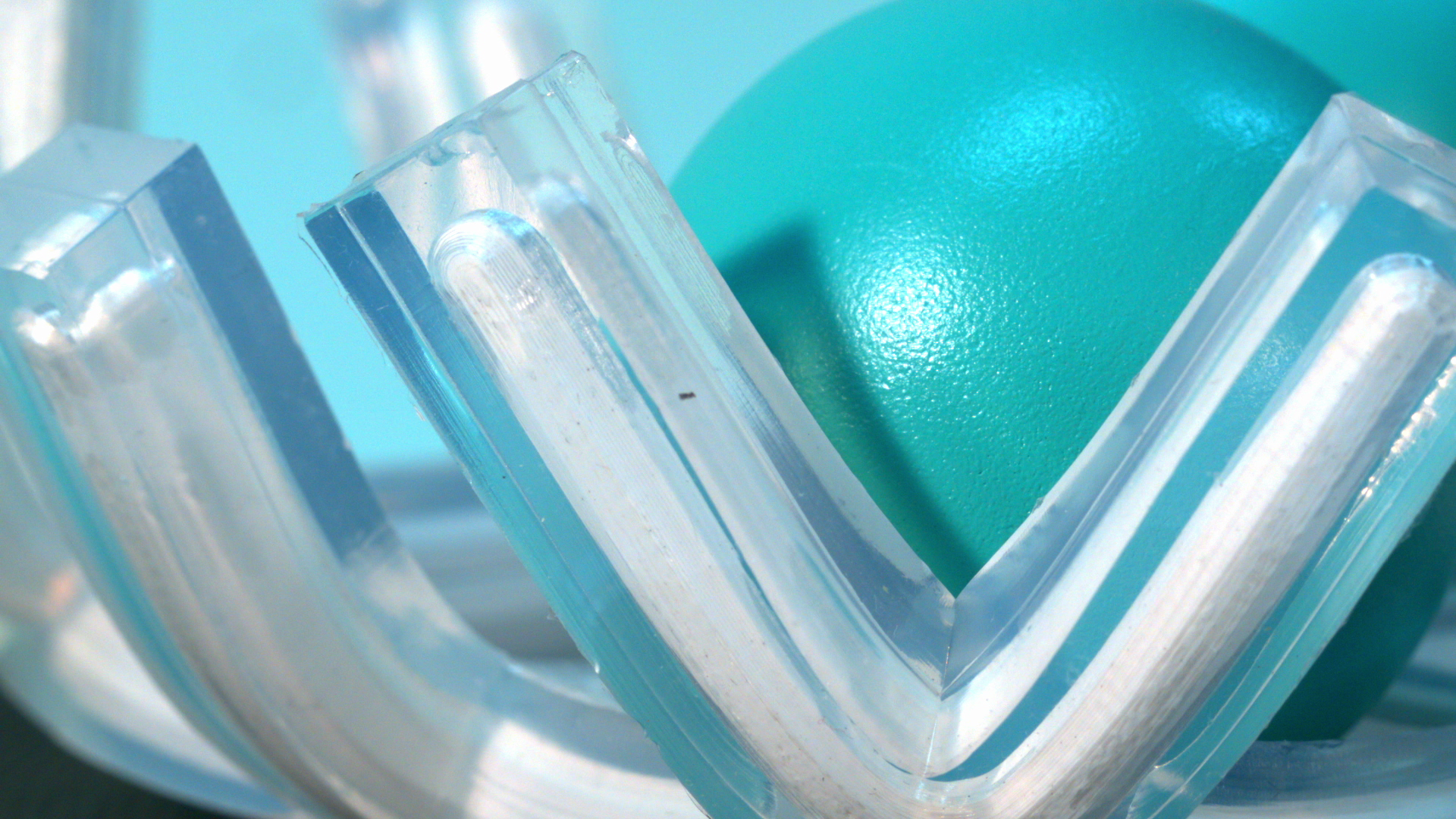

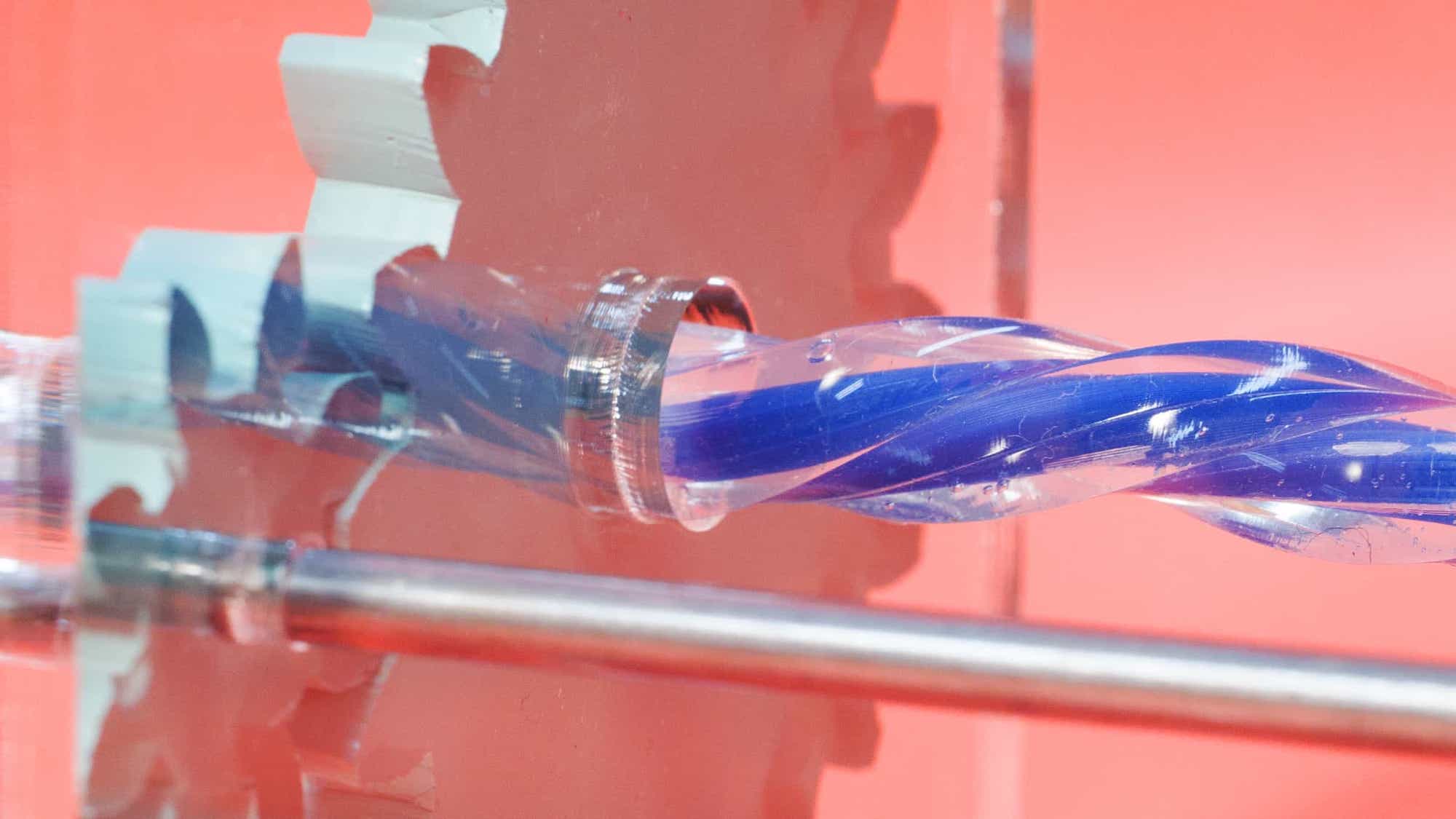

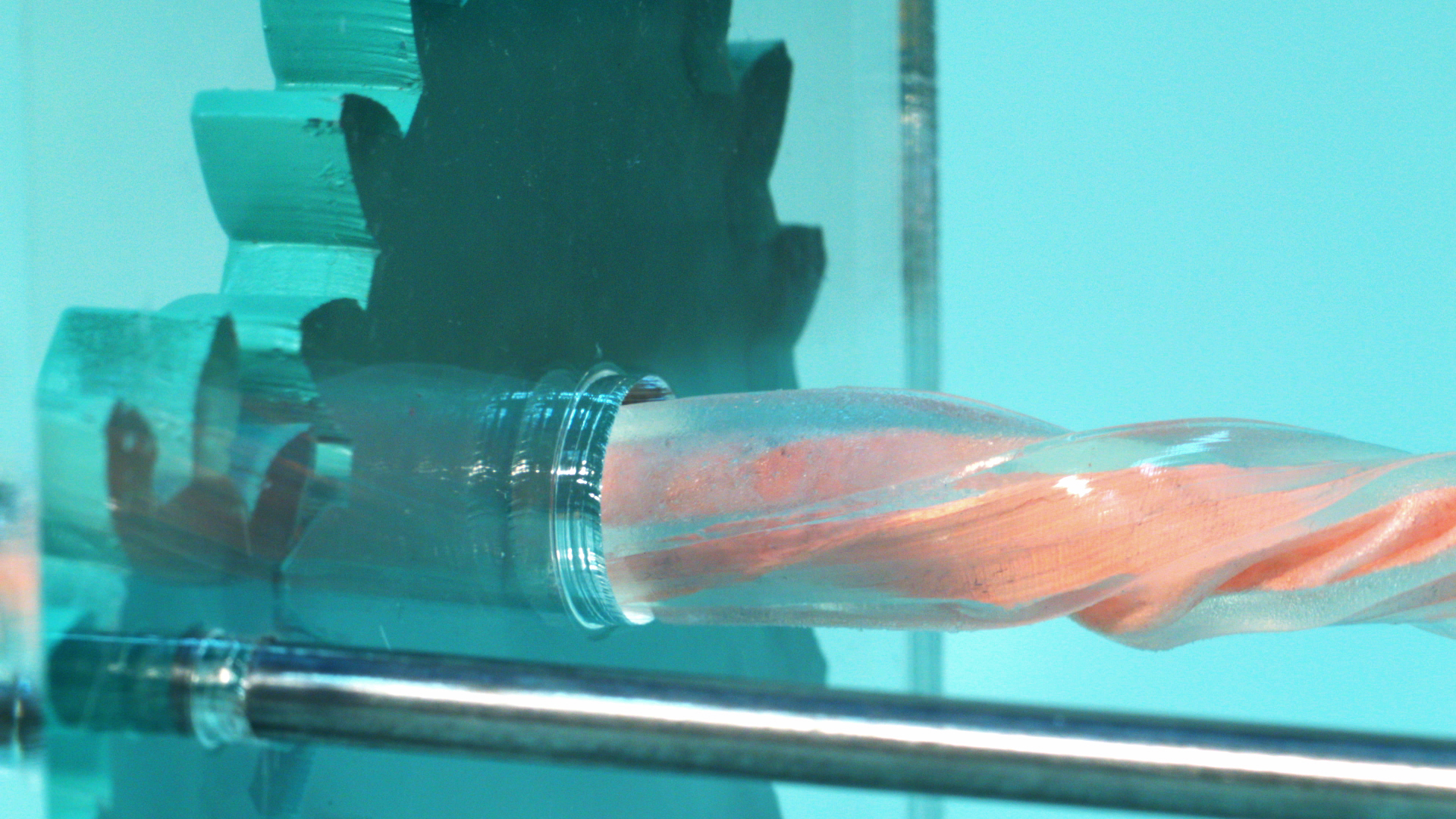

Inspired by natural processes of homeostasis, we set out to create an intelligent material that could be embedded into the everyday. Re:flex is a thermally responsive material: you can heat it, deform it into a temporary shape, and cool it down to freeze it in place. When heated again, it remembers and returns to its original shape.

Re:flex received a patent award from the Royal College of Art and was a finalist of the London Mayor Entrepreneur Competition in 2019. In the same year, we were invited by the Dutch Design Foundation to exhibit re:flex at the Dutch Design Week in Eindhoven and we participated in an exhibition organised by MaterialDriven for the London Design Festival. We were also selected to present our work at the Antenna Conference for the “world’s best design graduates” which is organised by Design Indaba.

Re:flex was featured by:

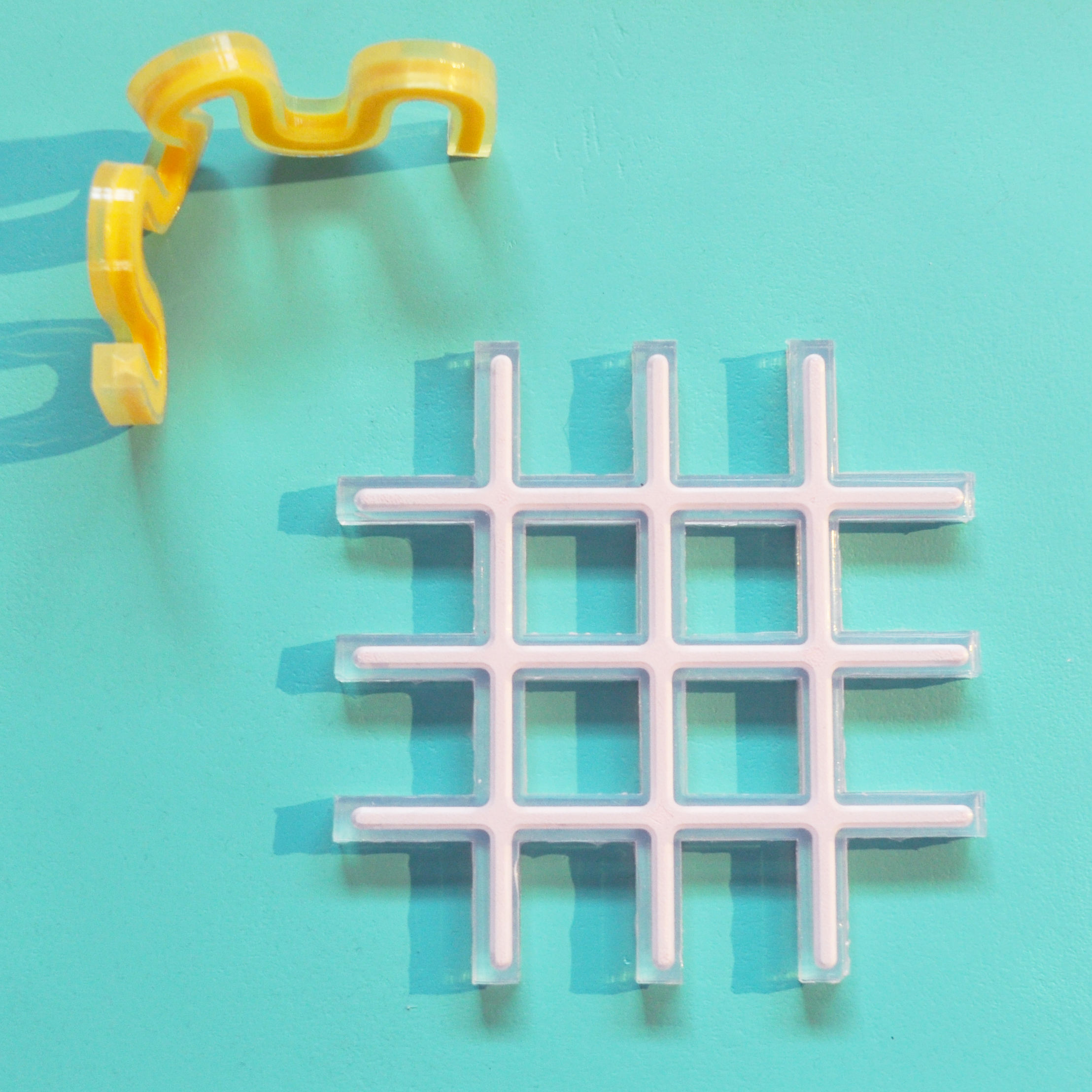

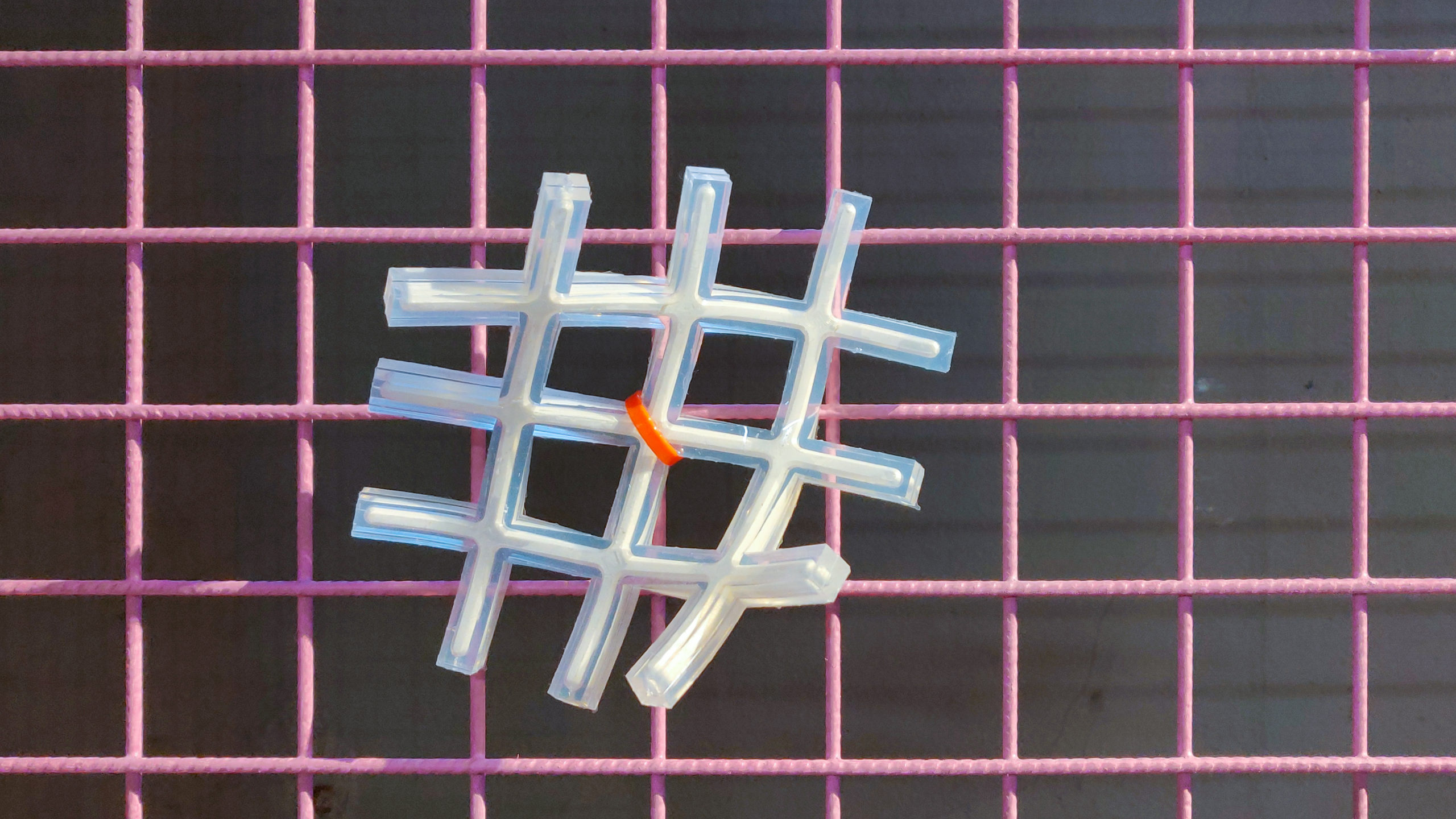

There are a few key things the material can do, which we have split into three main capabilities: reversible fixation, thermal actuation and unlimited fitting. To demonstrate these characteristics we have built three working prototypes that can be applied in different industries: an arm cast that can easily be applied, removed and reused (reversible fixation), a bicycle saddle that can be remoulded to suit its owner (unlimited fitting) and a stool with joints that can reconfigure themselves just with heat (thermal actuation).

Our material can be used for many applications, but to us the most important thing about re:flex is how it answers the question we asked ourselves at the beginning of our journey. By looking at how living organisms use the resources available to them to continuously adapt to changes in the environment, we too can develop technologies that help us adapt to changes in our lives without generating dangerous amounts of waste.

© Pierre Azalbert 2020